Fine Detail Cutting for the University of Texas!

Comments Off on Fine Detail Cutting for the University of Texas! We want to show you a cool part we just waterjet cut that really showcases one of the big advantages of waterjet cutting. This part was cut for the PMC lab at the University of Texas. The material is 1-3/4″ thick 7075 aluminum, and the ribs of this delicate lattice structure are only 1mm (.039″) wide! The through holes in the corners are only .130″ in diameter. This is a somewhat challenging job for even a waterjet, but it would be much more difficult or impossible to accomplish with nearly any other cutting or machining process.

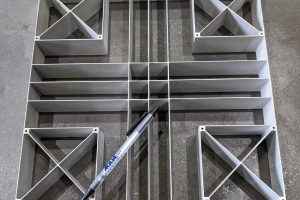

We want to show you a cool part we just waterjet cut that really showcases one of the big advantages of waterjet cutting. This part was cut for the PMC lab at the University of Texas. The material is 1-3/4″ thick 7075 aluminum, and the ribs of this delicate lattice structure are only 1mm (.039″) wide! The through holes in the corners are only .130″ in diameter. This is a somewhat challenging job for even a waterjet, but it would be much more difficult or impossible to accomplish with nearly any other cutting or machining process.

Most other cutting and machining processes involve a considerable amount of heat and/or force to shape the workpiece. Both heat and mechanical force are a big problem when you’re removing most of the material and producing a very delicate part. A waterjet leaves a cut surface that is unaffected by mechanical stresses or heat, making it ideal for cutting jobs with delicate features and fine detail.

Talking about the forces involved in a waterjet cut, we have some quick facts that we think you’ll find interesting. The same exact waterjet that we’ve used to cut metals up to a foot and a half thick exerts a mere 22 pounds of downforce on the workpiece during a pierce and less than 5 pounds of downforce during the cut! And yes, we do actually know this to be true. We literally pierced and cut material that was supported by a postage scale so that we wouldn’t have to lie awake at night anymore with such weighty questions on our minds…

If you find yourself burdened with weighty questions about waterjet cutting and how it works, please visit our TECHNICAL GUIDE TO WATERJET CUTTING which is an absolute trove of delightful facts and valuable knowledge. We promise it will be well worth your time!

-The crew at AquaJet