Which Materials a Waterjet Can Cut

Waterjet cutting is probably the most versatile cutting method in the world. Waterjets can cut almost any material, and they cut very accurately. The waterjet cutting stream is small enough to cut intricate parts, powerful enough to cut metals over a foot thick, and gentle enough to pierce through glass. In their areas of strength, waterjets are more cost-effective than other cutting methods. Finally, waterjets are environmentally friendly—they cut without gases or lubricants, and they do not produce smoke.

Waterjets can cut almost anything, and they do it through high-speed erosion. The material being cut determines which of two types of waterjet cutting will be used—either abrasive waterjet cutting or pure waterjet cutting, also known as water-only waterjet cutting. Abrasive waterjet cutting is used in all hard materials, and pure waterjet cutting is for soft materials. Abrasive waterjets can easily be converted to pure waterjets in a few minutes by switching to a different cutting head.

Materials That Abrasive Waterjets Can Cut

Abrasive waterjets cut with a supersonic stream of water mixed with particles of abrasive, usually garnet. The kerf, or the width of the cut, is commonly 0.030” to 0.050” (0.75mm to 1.25mm). Abrasive waterjets can cut almost any hard materials, such as:

- Metals—all types and hardnesses

- Natural materials—stone, glass, ceramic, wood

- Synthetic materials—carbon fiber, composites, fiberglass, plastics, hard rubbers

- Laminates—bimetals, thermocouples, stacked sheets of material

Waterjet cutting speed is inversely related to material hardness. In general, the harder a material is, the slower a waterjet cuts it.

To start a cut, a waterjet usually pierces a hole in the material. When cutting brittle materials like glass or stone, the pierce is done at a lower pressure to avoid breaking the material.

Materials That Pure Waterjets Can Cut

Pure waterjets, also known as water-only waterjets, are used for cutting materials that are soft enough to be cut with a knife. Pure waterjets cut with a small, high-velocity water stream only—no abrasive. The kerf is commonly 0.010” to 0.020” (0.25mm to 0.5mm). Pure waterjets can cut soft materials such as:

- Soft rubbers, foams, some polymers

- Textiles, carpet, leather

- Paper

- Foods—vegetables, candy bars, meat, etc.

Pure waterjet cutting is fast, it uses less water and power, and it consumes no abrasive. Whenever pure waterjet cutting is suitable, it is preferred over abrasive waterjet cutting.

Materials That Waterjets Cannot Cut

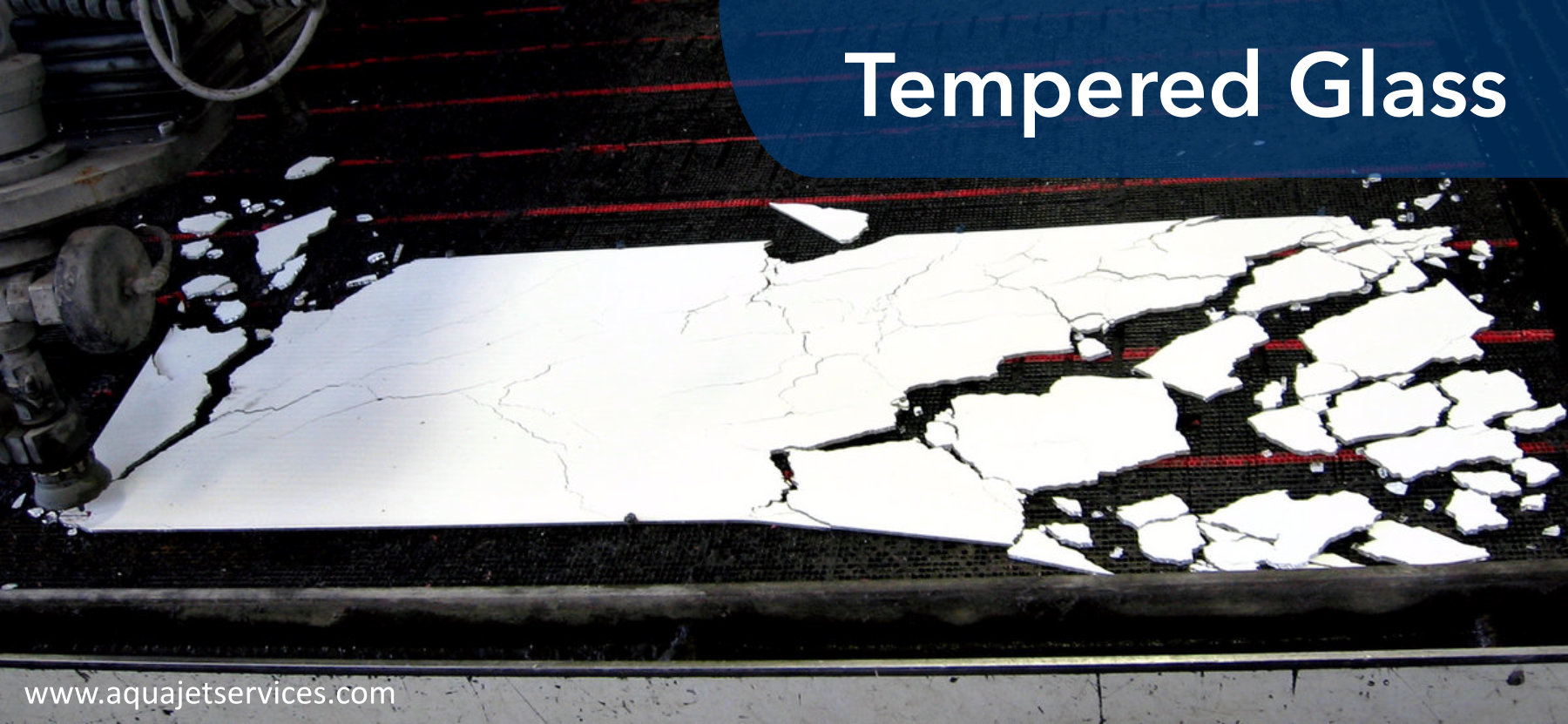

This list is short. Tempered glass cannot be cut because it has internal tension. It breaks itself when a cut crosses its tension zones.

To cut effectively, waterjets need to use abrasive that is harder than the material being cut. Therefore, the hardest ceramics can only be cut with specialized abrasives such as aluminum oxide and silicon carbide. Diamond cannot be cut effectively with waterjets because there obviously is no abrasive that is harder than diamond.

Thickness Range of Waterjet Cutting

Waterjets can cut an extremely wide range of thicknesses. There is no set limit on the maximum thickness that can be cut in hard, homogenous materials like metals. Waterjets are one of the few methods that can cut metals over a foot thick. However, waterjets are more limited when cutting thick textured materials like wood because the variations in density cause the water stream to oscillate.

Waterjets are also very good at cutting thin materials because multiple sheets can be stacked without sacrificing quality. For example, a stack of 100 sheets of 0.005” thick shim stock cuts at exactly the same speed as one 1/2” thick plate.